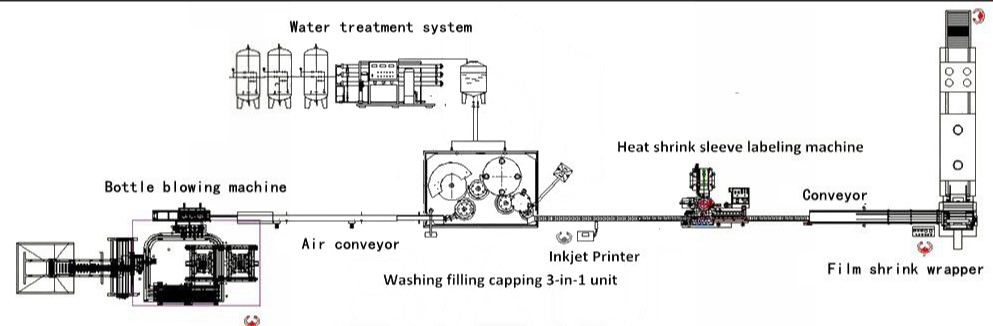

Filling machine workflow

With the rapid economic development of the world, both in light industry and heavy industry have been rapid development. For example, food manufacturing industry, wine, beverage manufacturing industry, agricultural and sideline food processing industry and other light industries have stepped into the full automation, in the process of automatic production filling machine is an essential equipment for these industries. With the rapid development of science and technology, the function of filling machine as an important production equipment in light industry is becoming more and more powerful. Today, I will talk to you about the working process of filling machine.

The following is the liquid filling machine:

1. Place empty bottles on the tray and transport by the conveyor belt.

2. The pallet is transported to the unloader, unloaded one by one, and the box is brought to the unloader along with the conveyor.

3. Remove the empty bottle from the box and transport the empty box to the washing machine for cleaning, and then to the packing machine.

4. The empty bottle is sent into the washing machine by another conveyor belt for disinfection and cleaning.

5. Enter the filling machine and the cover machine after the inspection.

6. The drinks are bottled by the filling machine.

7. Cover the beverage bottle with confidential seals.

8. Send it to the labeling machine.

9. After labeling it, pack it, and then send it to the stacker and stack it on the tray.

10. Finally delivered to the warehouse.

This is the orderly working step of the liquid filling machine, each step is accurate and efficient, together to ensure the smooth progress of the filling work. Hopefully these steps will give you a deeper understanding of liquid filling machines. Let's witness the power of science and technology in production!

This is the orderly working step of the liquid filling machine, each step is accurate and efficient, together to ensure the smooth progress of the filling work. Hopefully these steps will give you a deeper understanding of liquid filling machines. Let's witness the power of science and technology in production!